Solid surface worktops have been a fixture in kitchens and bathrooms for more than 50 years. With the exception of quartz, very few countertop materials have managed to acquire the same prestige as what could have once been deemed trendy.

Sintered stone is a new type of ultra-size porcelain slab made up of natural components, including quartz minerals, clays, feldspar, silica, natural mineral pigments, etc.

The mineral composition and stone particles are carefully selected based on the quality, color, and texture.

The manufacturing process applies modern advanced technology to imitate the formation of natural stone. The roller machine (over 4,200 tons of weight) presses and shapes the raw materials at a high temperature of more than 1,200°C. This is exactly what marble and granite experienced thousands of years before they were formed. In this way, the particles can be permanently and firmly bonded together without the need for resins or adhesives, perfectly recreating the texture and feel of precious natural stone.

Generally, the sintered stone is made to look like natural materials, such as stones, wood, and other smooth or textured surfaces. And it can withstand high-intensity machining, which includes cutting, drilling, and grinding. Therefore, it is often processed into sintered stone furniture, like sintered stone dining tables, sintered stone countertop, etc.

Wanna Know More About the Sintered Stone?

HEALTHY AND SAFE

The sintered slab can directly contact with the food, as it is derived from 100% pure natural materials and has reached the food safety level. It is high density with anti-permeability, so it is stain-resistant and can effectively reduce the breeding of bacteria, to ensure the sintered slate will never deteriorate.

HIGH UV RESISTANCE

The sintered slab can effectively fight against ultraviolet rays, as it is equipped with water penetration, heat insulation, and frost resistance. Meanwhile, it can maintain the color continuity without fade under long-time wind and sun exposure, a great option for exterior building material.

FIREPROOF AND HEAT-RESISTANCE

The sintered slab is classified as A1 fire-rating products which means it is non-combustible. When it directly contact high-temperature objects, there will be no deformation, no physical changes such as contraction, cracking, and discoloration, and no gas or smell in the 2000 ℃ (3632°F) open flame.

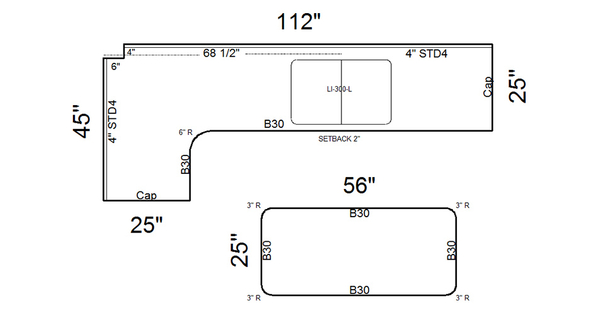

FLEXIBLE CUSTOMIZATION

The sintered slab can be made of different sizes, textures, and colors, polished or matt, etc. The size of the sintered slab finish can reach 3000*1500mm at present, which can not only speed up the installation process but also enhance the visual effect and upgrade the sense of space.

The popularity of sintered slab has steadily grown in recent years, and it is foreseeable that it will be the trend of the future.

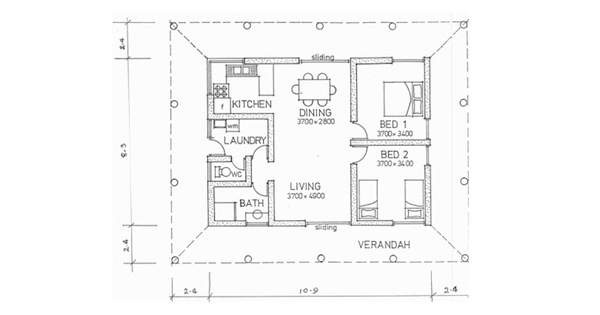

As the sintered slab adds much value to both interior and exterior designs, it enjoys a wide range of application, usually including indoor living room, bedroom, kitchen, bathroom & balcony, outdoor garden patios, landscaping, gardening, furniture like countertop, vanity, tabletop, cabinet, and some public premises.

Need Project Help?

Looking for a Reliable Sintered Stone Supplier?

The sintered stone slab is a new and innovative covering material. It is made of 100% natural minerals, which are pressed by extremely high pressure (over 3900 PSI) and fired (over 1200 ℃) in a kiln. This gives the product outstanding physical and mechanical properties in terms of compaction, resistance, and durability. The production process of sintered stone slab as follows:

Want a Free Sample?